Powder Bulk Packaging Filling Machine Semi-Automatic Quantitative Vertical Powder Packaging Machine

Overview Product Description Product Features: 1. Design for weighing and filling packaging powdery materials.2. The mac

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | TSF10-50 |

| After-sales Service | Life Time |

| Warranty | One Year |

| Automatic Grade | Automatic |

| Application | Cleaning, Detergent, Cosmetics, Drinks, Skin Care Products, Dairy Products, Hair Care Products, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Seasoning |

| Type | Forming Filling Sealing Machine |

| Forming Species | Box Molding |

| Forming Function | Forming, Filling, Seal |

| Driven Type | Electric |

| Material Type | Powder |

| Packaging | Bag |

| Packaging Material | Plastic,Paper,Woven Fabric |

| Appllied Material | Dry Powder |

| Capacity | From Small Lab Scale to Industrial Bulk Production |

| Power Supply | Customized as Per Customer Request |

| Steel Material | Stainless Steel SUS304#, SUS316L, Ti Alloy, etc. |

| Sample Test | Available |

| Explosion Proof | Available |

| Germ-Free | Available |

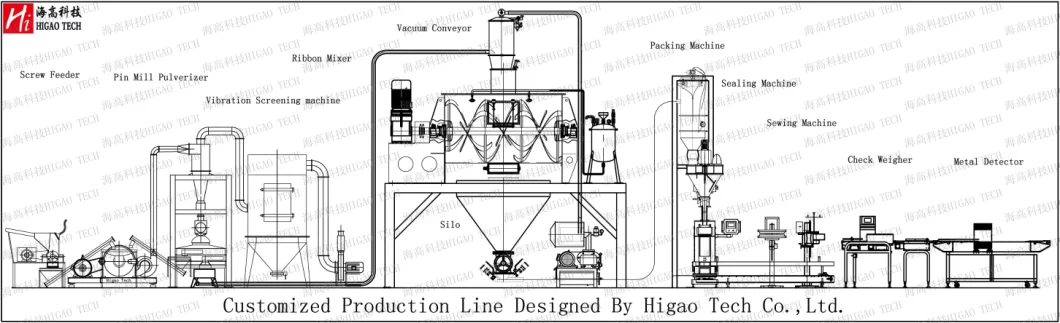

| Turnkey Production Line | Available |

| Transport Package | Standard Export Packing |

| Specification | TSF10-50 |

| Trademark | Higao Tech |

| Origin | China |

| HS Code | 8422 |

| Production Capacity | 500 Sets/Year |

Product Description

Product Features:

1. Design for weighing and filling packaging powdery materials.2. The machine use double auger screw feeder to weigh powder.3. Adopt a new international popular production control system: high-precision and high-speed special measurement control instrument, with strong function, high reliability and great flexibility and extendable characteristics, fully adapted to the repeated and high-intensity continuous production process.

4. It has the functions of overshoot suppression, automatic drop correction, automatic alarm for over-difference, etc.

5. The machine is a new equipment combined mechanical and electrical integration. It adopts computer control technology, imported high-precision weighing sensor.

6. The size of the bag holder can be changed and adapted to many sizes of packaging bags.

7. There are chemical industry belt, plastic steel chain plate and other material structural conveyor belt can be selected from.

8. There are industrial sewing machine and pneumatic thermal sealing machines are available.

9. We can deploy industrial vacuum cleaner for you.

10. The whole machine is made of stainless steel.

11. The design is practical and beautiful.

12. The key equipment is all famous brands.

13. The machine also can be customized for you.Detailed Photos

Product Parameters

| 5~25kg Large Dose Powder Twin Screw Feeding Bag Filling Machine of Higao Tech | |

| Model | TSF10-50 |

| Weighing method | Direct weighing type (gross weight) |

| Feeding mode | Double screw |

| Filling weight | 10~50kg, 20~100kg |

| Filling accuracy | ±0.1% |

| Filling speed | 2~4 bags/Min |

| Total motor power | 3.9kw |

| Compressed air supply | 0.6~0.8Mpa, 0.2M3/Min |

| Control method | PLC |

| Control display | Touch screen |

| Machine weight | 400kg |

Why choose us?

1. Real Steel Material: we have spectrometer for customer to check the material.

2. High machining accuracy: we use top brand CNC machining center, plasma and laser cuting machines, etc. to process components.

3. Professional work team: 10 engineers more than 20 year experience in R&D. Some production staff more than 30 year experience.

4. Standard production rules: we follow 5S industrial management standard to carry out our orders.

5. Strict quality control: we have QC to follow and check each working procedure as per industrial standard.

6. Customer approval: we have served more than 1000 customers in more than 50 countries.

7. Competitive price: German quality with Chinese price.

FAQ

1. How can I know your quality?

Our company is famuous in our industry. We have more than 20 years history. The best way to know the quality is comparison. You can come to our factory for on-the-spot investigation. You are welcome.

2. Can you supply sample test?

Of course our company can supply sample test before buying. And record the testing result and send to you by pictures or video.

3. What is your delivery time if I place order?

Usually 30~60 days. It depends on the machine itself, our actual order status.

4. Can you supply installation and commissioning service abroad when we received our equipment?

Yes, our company can send our engineers to your local workshop to guide installation and commissioning and training your operators.

5. How to operate and maintain the machine?

We will give you operation manual, drawing, circuit diagram spare parts list, etc after shipping.

6. What should I do if we can not solve the problems some times?

You just need to send email or make a call to us. We will reply within 12 hours and analyse the problems with you. Find the reason and find the way.

If we can not solve by communication after trying several ways, we can send our engineer to your place if you need.

7. What is your warranty period?

We supply one year warranty and life time after sales service for our euqipment.

Related Products

-

![50-300 Pigs Agricultural Slaughtering Machine Pork Carcass Killing Dehairing Machine Meat Processing Machine for Slaughtering Machine]()

50-300 Pigs Agricultural Slaughtering Machine Pork Carcass Killing Dehairing Machine Meat Processing Machine for Slaughtering Machine

-

![Heavybao Electric Commercial Frozen Meat Cutting Machine Bone Cutting Saw Machine for Restaurant]()

Heavybao Electric Commercial Frozen Meat Cutting Machine Bone Cutting Saw Machine for Restaurant

-

![Tea Bag Nitrogen Sealed Inner Outer Tea Packing Machine]()

Tea Bag Nitrogen Sealed Inner Outer Tea Packing Machine

-

![Industrial Meat Bowl Cutter/ Meat Cutting Mixing Machine /Meat Chopping Machine]()

Industrial Meat Bowl Cutter/ Meat Cutting Mixing Machine /Meat Chopping Machine